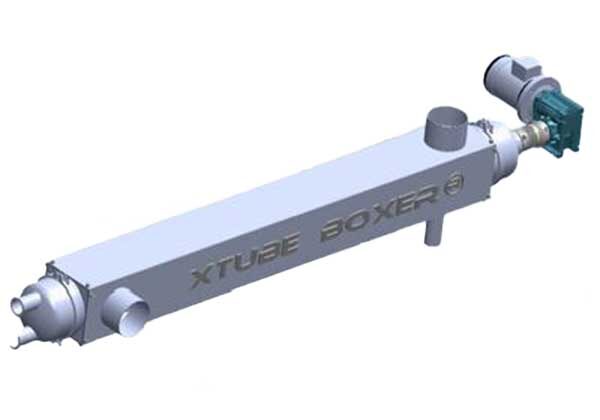

The Xtube Boxer heat exchangers are a type of Scraped Surface heat exchanger developed under the patent of the XLG company.

As the service fluid (for heating or cooling purposes) passes through the inner part of the tube bundle of the tubular heat exchanger, the product passes through the shell part in contact with the outer surface of the tubes. The heat exchanger is equipped with an electric motor and reducer group, which drive a piston back and forth through a rotor. The scraping elements driven by this piston continuously clean the outer surface of the tubes through which the product passes. Additionally, this process prevents product mixing and the formation of undesirable elements that could affect the product, such as burning.

It has been designed and manufactured according to the European Pressure Equipment Directive (97/23/EC) and its specifications, and the CE mark is provided if necessary.

Applications:

Heating or cooling applications for fluids with viscous and adhesive properties.

Heating of heat-sensitive products.

Cooling of products at risk of crystallization.

Materials:

Except for the scraping elements, wet surfaces, stainless steel AISI – 316L is used for tubes and other wet surfaces. The scraping surfaces are made of various combinations, including copper-nickel alloys, stainless steels, or, depending on the application, plastics (PEEK, etc.). Corrosive liquids may use Austenitic (duplex) steels in processing.

Surfaces not in contact with the fluids are made of AISI 304 stainless steel.

Connections:

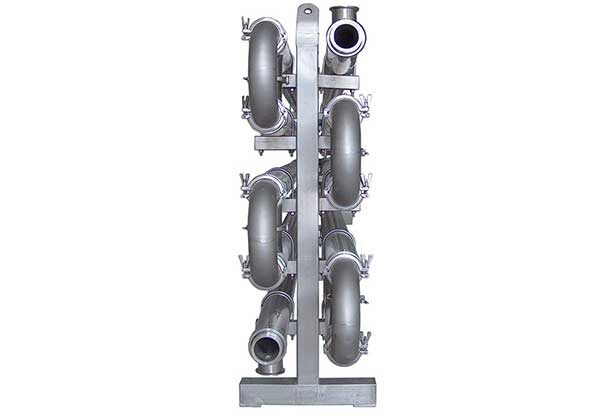

To facilitate ease of installation and flexibility, ISO standard clamps are used for all connections of the XTube Boxer® heat exchanger.

If necessary, ferrules, gaskets, and high-pressure clamps can be provided to ensure compatibility with the heat exchanger’s installation and pipe system.

Design Conditions:

Temperature Minimum / Maximum Allowed: -40°C / +400°C

Pressure Minimum / Maximum Allowed: Vacuum / 10 Bar (g).

Higher pressures and temperatures are possible upon request.

Standard Sizes:

XTube Boxer® B-Type heat exchangers are available in various lengths, with standard sizes being approximately 3000 and 6000 mm.

Standard models have heat transfer surfaces in the range of 10-60 m2.

They can operate in either a vertical or horizontal position.